PDR equipment (Paintless Damage Repair) is revolutionizing auto body painting and repair by fixing dents, scratches, and dings without traditional methods, saving time, money, and reducing waste. Before investing in new PDR tools, assess your workshop layout and current tools for improvements. During setup, prioritize safety with proper ventilation, gear, and manufacturer instructions. Master new equipment through trial runs and maintain them regularly for optimal performance.

Looking to transform your workshop into a cutting-edge automotive repair hub? Upgrading with new PDR (Paintless Dent Repair) equipment is a game-changer. This article guides you through the process, from understanding the benefits of PDR technology and its versatile applications to evaluating your current setup for a seamless transition. We provide a step-by-step implementation guide, ensuring you make informed decisions when investing in top-tier PDR equipment.

- Understanding PDR Equipment and its Benefits

- Evaluating Your Current Workshop Setup

- Implementing New PDR Equipment: A Step-by-Step Guide

Understanding PDR Equipment and its Benefits

PDR equipment, or Paintless Damage Repair tools, is a game-changer for auto body painting and automotive repair services. These innovative tools allow professionals to fix dings, dents, and scratches on vehicles without the need for traditional sandblasting or repainting. By leveraging specialized equipment like PDR hammers, pulls, and dryers, technicians can restore damaged surfaces to their original condition, saving time and money.

The benefits of investing in PDR equipment are significant. It streamlines the repair process, reduces waste, minimizes the use of harmful chemicals, and maintains the vehicle’s original factory finish. Moreover, PDR techniques enhance customer satisfaction by providing a faster, cleaner, and more cost-effective solution for auto body repairs. This not only boosts business reputation but also fosters customer loyalty among those who value eco-friendly and efficient auto repair services.

Evaluating Your Current Workshop Setup

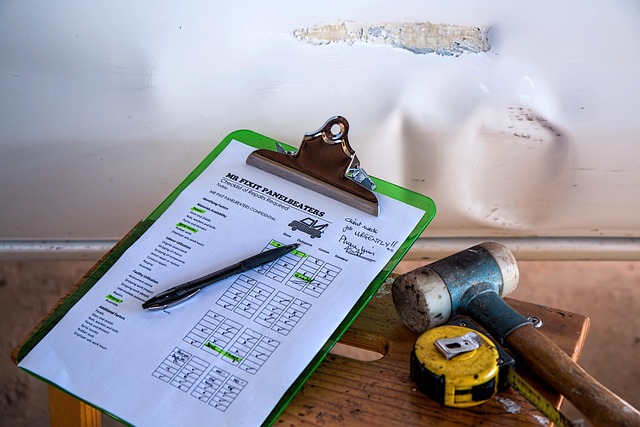

Before upgrading your workshop with new PDR equipment, it’s crucial to evaluate your current setup. Take a good look at the space and the tools you already have. Identify areas where improvements can be made—for instance, if your existing tools are outdated or don’t align with modern auto repair services and fender repair techniques. Consider the flow of work; is there enough room for efficient movement between stations? Are there adequate power sources and ventilation to support new equipment?

This assessment will help determine what specific PDR equipment upgrades are necessary, whether it’s advanced tools for more precise auto body painting or specialized machines for streamlining fender repair processes. By understanding your needs and current capabilities, you can make informed decisions about the best investments to enhance your workshop’s functionality and productivity.

Implementing New PDR Equipment: A Step-by-Step Guide

Implementing new PDR (Paintless Damage Repair) equipment is a strategic process that can elevate your workshop’s capabilities significantly. Start by assessing your current tools and identifying areas for improvement. This might involve replacing outdated equipment or adding specialized tools for various car damage repair scenarios, such as frame straightening. Once you’ve made a list of required PDR equipment, research and compare different brands and models to find the best fit for your budget and needs.

Next, prioritize safety during installation. Ensure proper ventilation, wear protective gear, and follow manufacturer instructions carefully. After setting up the new equipment, conduct trial runs with dummy vehicles or panels to familiarize yourself with their performance. This step is crucial in mastering the use of new tools and techniques, especially for intricate vehicle collision repair tasks. Regular maintenance and calibration will also be key to keeping your PDR equipment running optimally over time.

Upgrading your workshop with new PDR (Paintless Dent Repair) equipment can significantly enhance your auto repair capabilities. By understanding the benefits of this technology and evaluating your current setup, you can make informed decisions when implementing new tools. Following a structured step-by-step guide ensures a smooth transition, allowing you to offer advanced services and stay ahead in the competitive automotive industry. Investing in PDR equipment is not just about improving aesthetics; it’s a strategic move to expand your workshop’s capabilities and attract customers seeking modern, efficient repairs.